CNC HONING TOOLS

Hard Turning operations performed on modern CNC lathes have reached levels of precision and repeatability that overlap, in many cases, those obtained with grinding operations.

In many cases, however, very precise roughness parameters are required or the absence of helical processing marks that can not be obtained with the turning process, which therefore requires a subsequent honing step carried out on a special machine.

Here our CNC honing machines are needed, which are used in the last processing phase for surface finishing.

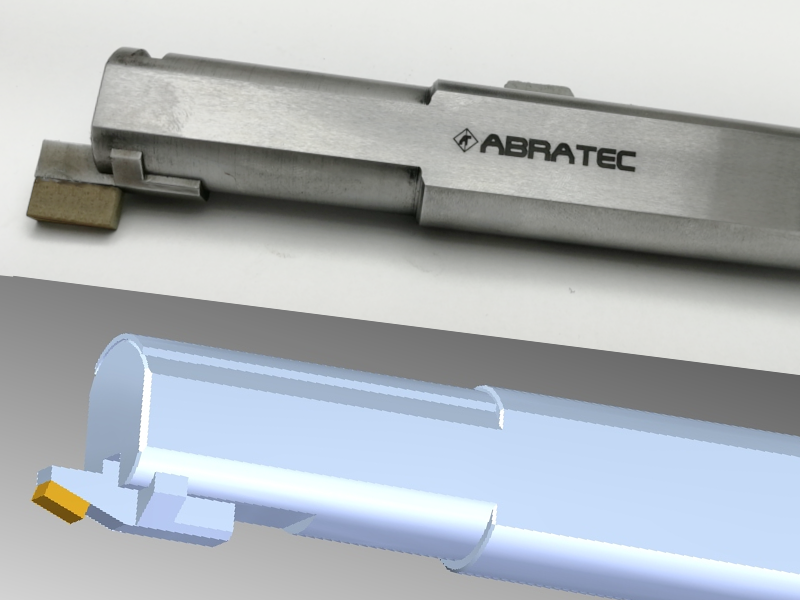

Handled directly on the CNC lathe, through the tool change, they consist of an abrasive pad in CBN or Diamond, mounted on a floating and spring-loaded support.

At the end of the turning, after an accurate washing operation of the piece with the lubricant-cooling fluid present on the machine, the abrasive pad is brought into contact with the surface to be honed, translating with the longitudinal axis while the piece is rotating.

Processing takes place in wet conditions, using the machine’s cooling lubricant; the only precaution required is the total absence of chips in the work area.

The working feed is obtained by advancing with the machine axes.

It is possible to adjust the working pressure by means of a special rivet which loads the internal spring.

Thanks to the quick change system of the abrasive pad, the same tool can be used to obtain different finishing levels.

The removal of material is usually negligible; often less than 0.001 mm, so the dimensions obtained during the turning operation are not substantially altered.

This type of tools is produced in various shapes and sizes to work both on internal and external diameters, also conical, as well as on circular razor crowns.

Our specialists are available to recommed the solution that best suits your needs.

ABRATEC srl

Via Datini,23 - 50126 Firenze - Italia

Tel +39-055-6812093 - +39-055-6813259

Fax +39-055-6813049

© 2024 Abratec srl - C.F. & P.I. 04888570480 – R.E.A. 497881

MENU